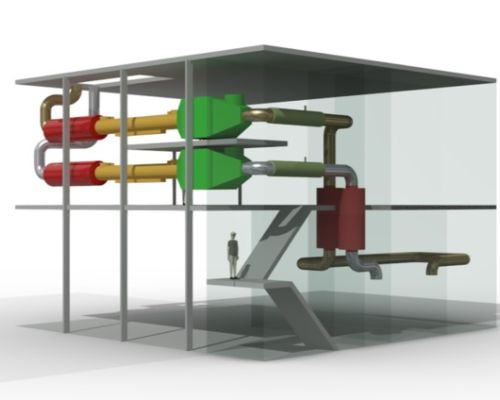

CHP Plant Vathorst - DeNOx modification

The CHP produces electricity and heat to supply to the surrounding households. Due to new legislation for emission of flue gasses a DeNOx/ SCR catalyst is to be integrated In the flue gas system. Eneco has awarded Array Industries the contract for Turn-key modification of the complete flue gas system for 12 engines (1,6 – 1,9 MWe each)

Project scope:

- Detailed engineering of flue gas system (process & mechanical)

- Fabrication of ducting; frame, lifting frame & stack

- Installation of silencers/ ‘pre’ coolers, Urea injection system, SCR

- Installation of Urea system

Engineering consisting of:

3D modelling / process & mechanical design / Pipe stress analysis / Pressure drop calculations / silencer design / cooler design / thermal design of complete system

Challenge

Comply with new regulations with limited footprint (12 systems)

Solution

Design and integration of new CHP Balance of Plant:

- SCR’s

- EGHE’s

- Silencers

- Dust filters

- Piping and stacks

Facts

Customer:

Eneco Solar, Bio & Hydro B.V.

Location:

Netherlands

Benefits

Better engine performance with lower system back pressure.

“Array has ensured that we comply with the regulations - within budget and within the set timeframe - and the performance of the engines has also been improved!"

Martin Kiep

PROJECTMANAGER

Eneco Solar & Wind

Solutions:

DeNOx, SCR/Oxycat, Silencers, Stack