Utrecht University - SCR integration

Challenge

Retrofitting a DeNOx system in an existing Cogen Plant, consisting of five 2.2 MW Natural Gas Powered Engines, with minimal downtime and no major modifications to the existing building structure.

Solution

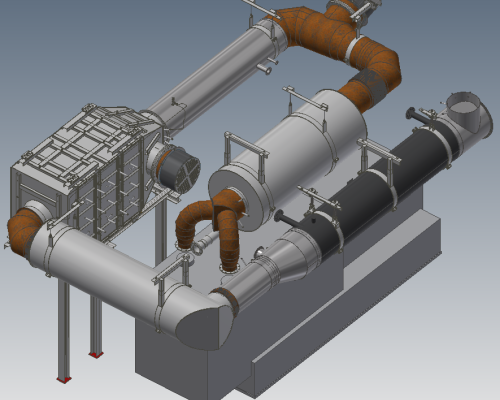

A bespoke exhaust system between the engine and stack, containing:

- Silencers

- Selective Catalytic Reactors (SCR)

- Tailored urea delivery system

- Heat Exchangers (EGHE’s)

- Explosion Relief Panels

The system has been designed to meet max. pressure drop requirements and sound levels.

A tailor made and identical layout for each engine room.

Facts

Customer:

Utrecht University

Location:

Utrecht, the Netherlands

Benefits

- Single point of contact for complete scope

- Better engine performance due to lower system back pressure

- Implemented without disturbing the existing engine room layout or building outline

- No more than two engines were modified at the same time, allowing power and heat generation to continue during the modification activities

- The system has an additional 25% capacity available for potential higher emission restrictions in the future

Solutions:

Process ducting, SCR/Oxycat, Silencers