Down time of processes is killing in Oil & Gas! The prevention of down time grows the demand for reliable systems in Oil & Gas, especially in combination with unmanned operations. But how to secure reliability in design processes? The answer to that is in our opinion HAZOP. By zooming in on redundancy and system safety reliability is integrated in the design. For that reason we operate a HAZOP team with chairman and scriber including the necessary software who have the experience in performing HAZOP for multiple processes.

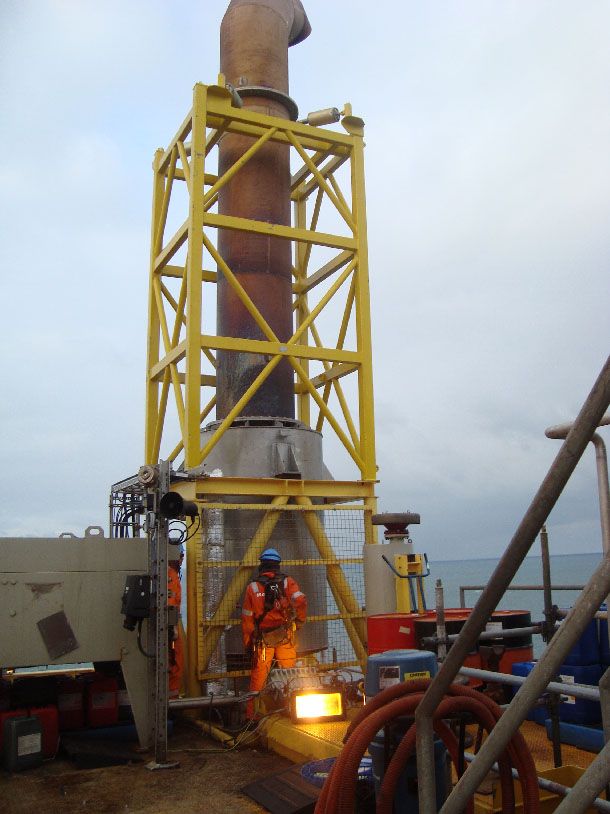

The Array engineering team designs custom made solutions to emit exhaust gasses from gas turbine or generator sets in line with specifications. We propose a process design followed by a mechanical design. In the design we incorporate noise emission, material choice, thermic insulation, ATEX zoning, limited installation space, offshore installation and transport limitations. The design is being developed in close contact with your project team. Our project manager is the connecting link. He brings all disciplines together and assures the project is executed according plans and contract. He is your single contact from design to start up.

Hoogeveenenweg 93

2913 LV Nieuwerkerk aan den IJssel

Nederland

+31 (0) 10 765 12 00

Made with Schot Marketing & Communicatie - login

Hoogeveenenweg 93

2913 LV Nieuwerkerk aan den IJssel

Nederland

+31 (0) 10 765 12 00

Privacy Statement